PANELFISA TRUSTS IN PRODUCTION METROLOGY TO OPTIMIZE TIMES AND IMPROVE THE QUALITY OF ITS FASTENING ELEMENTS.

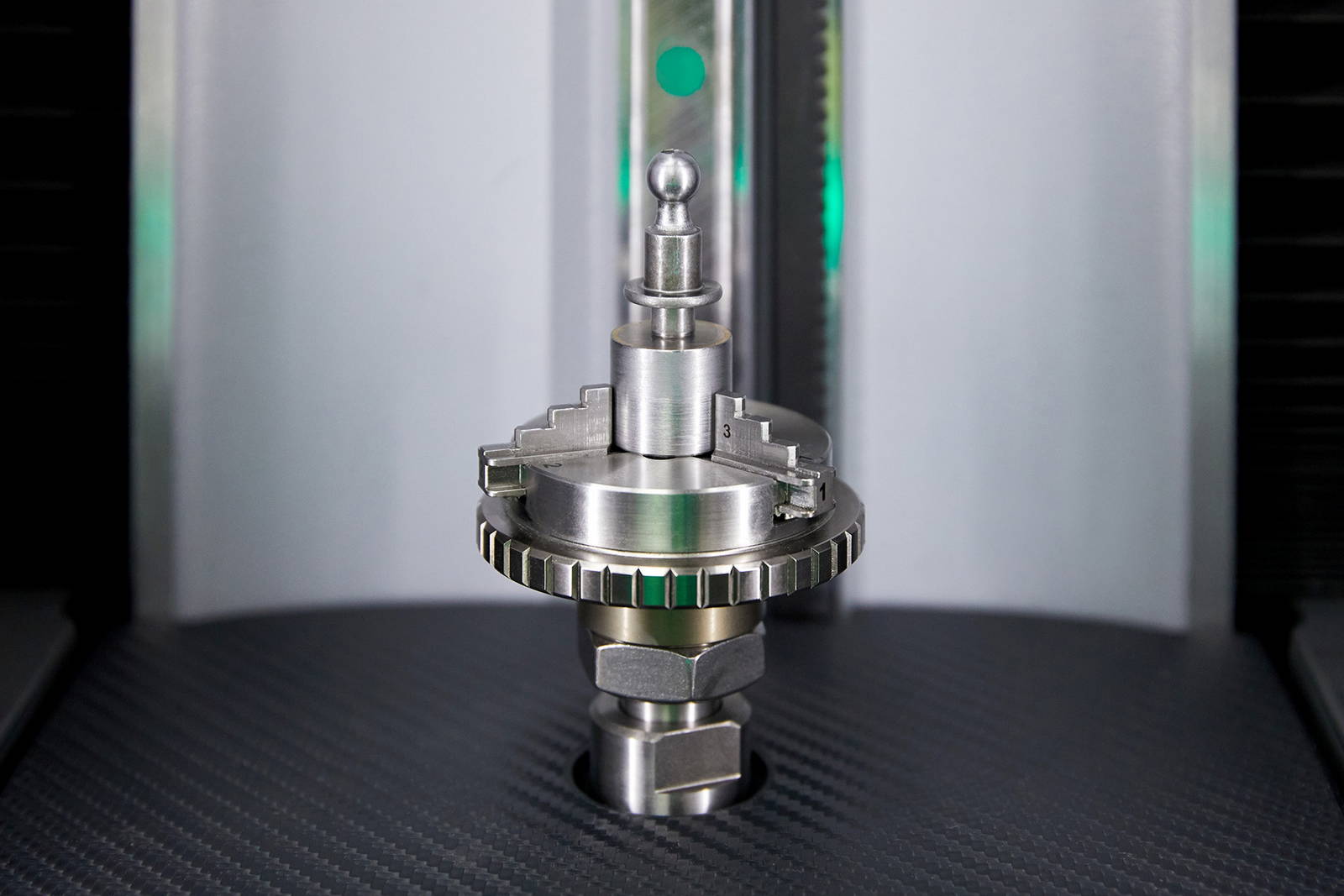

Panelfisa is a global supplier of fastening elements produced by cold stamping and specialized in the automotive sector. We are committed to innovation to grow together with our customers.

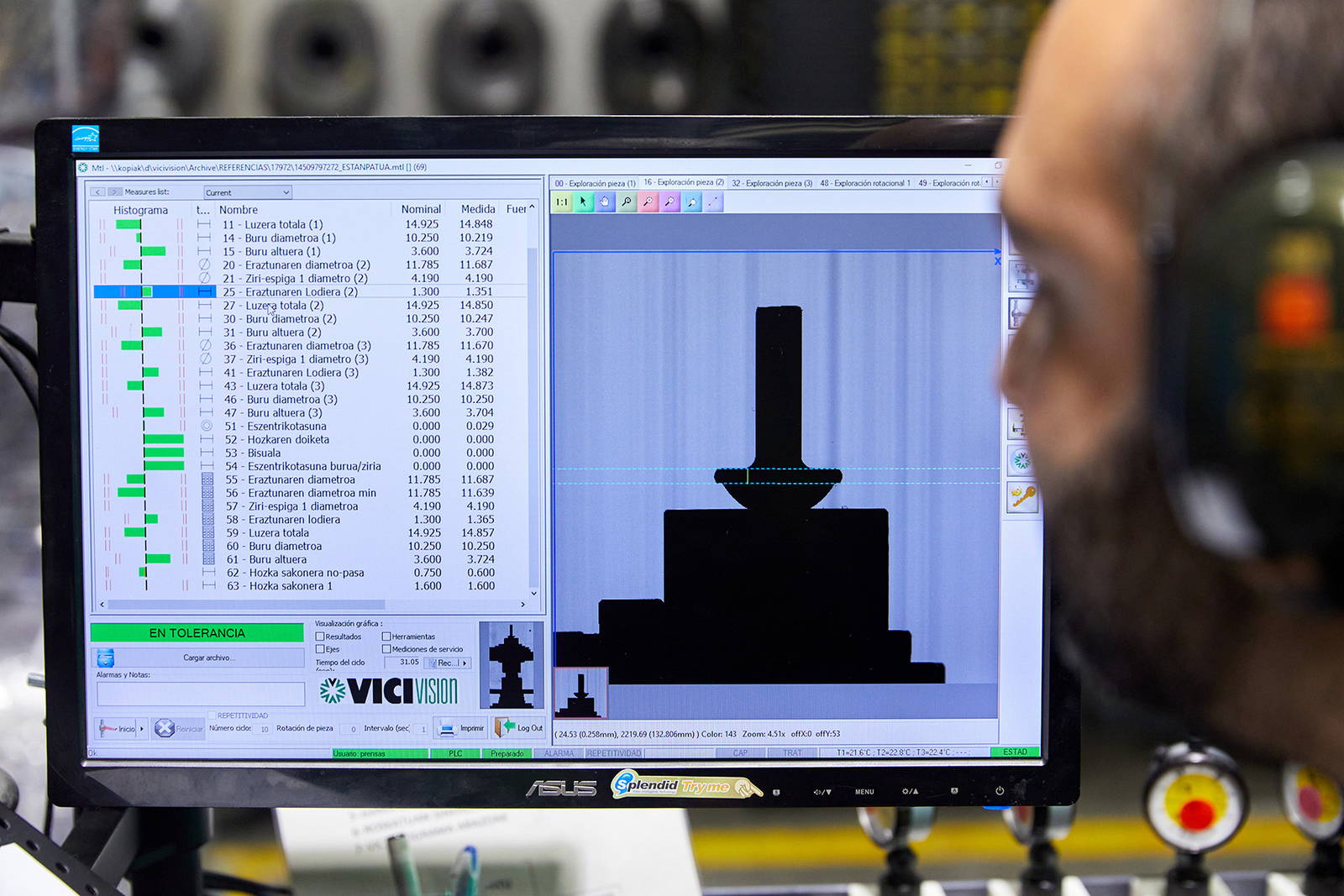

In 2015 we bought an MTL1 machine from VICIVISION to reduce times and make measurements more reliable by automating measurements that were previously carried out by hand. The intention at the beginning was to give direct support to production but finally the machine was installed in the laboratory and we started learning how to use it.

We visited different companies around in which they had already implemented VICIVISION technology and gave direct support to production. We were aware of the advantages this entailed for production, so we decided to launch a project between Kepa Ezeiza and myself to integrate a VICIVISION machine into our production.

Thanks to the project, we gained great knowledge of the VICIVISION machine and applied it to our cold stamping process. People began to see the advantages offered by the VICIVISION machine, the insecurities disappeared and thanks to this we were able to gradually implement the machine in production.

Now we measure faster, with more reliability, we can give traceability to the measurements we have made, we have accelerated the validation process of the parts and we have also considerably improved the percentage of complaints, rejection and internal scrap.

A total of 5 VICIVISION machines give direct support to production. We have different cold stamping, threading, laminating and machining machines. We have reduced the measurement time between 30 and 50 seconds depending on the part, now we give 100% traceability to the process thanks to the manufacturing orders and the VICIVISION measurements.

We have a central program to save only the measured dimensions. In this program all the machines in the workshop appear divided by equipment, this allows us that anyone al Panelfisa can measure any type of part on any vici vision machine and can save the data in any of these machines. This solves any type of saturation that we may have.

Now, Vici Vision technology is taken into account from the beginning in all approvals.

The next step in this project is the implementation of VICIVISION technology in the threading section and the standardization of the stamping and threading process in the Mexico plant.

To conclude, say that this project has been carried out thanks to the close collaboration between Sariki and Panelfisa.