Medical Precision Implants was founded in 2008, supported by its parent company Nagamohr.

Nagamohr is a company that exists since 1992, currently has 150 employees and manufactures 22 million implants.

With Sariki’s help, official dealer for VICIVISION in Spain, we can measure them constantly from the beginning, and these high-quality implants are exported worldwide.

In 2008 MPI was founded to supply the dental implant and prosthetic market, and Sariki is still supporting us in this effort since our inception.

Some years ago, MPI set to improve its traditional measurement methods. To this date, all parts were measured with profile projectors, micrometers, calipers… and this took the technicians a considerable amount of time.

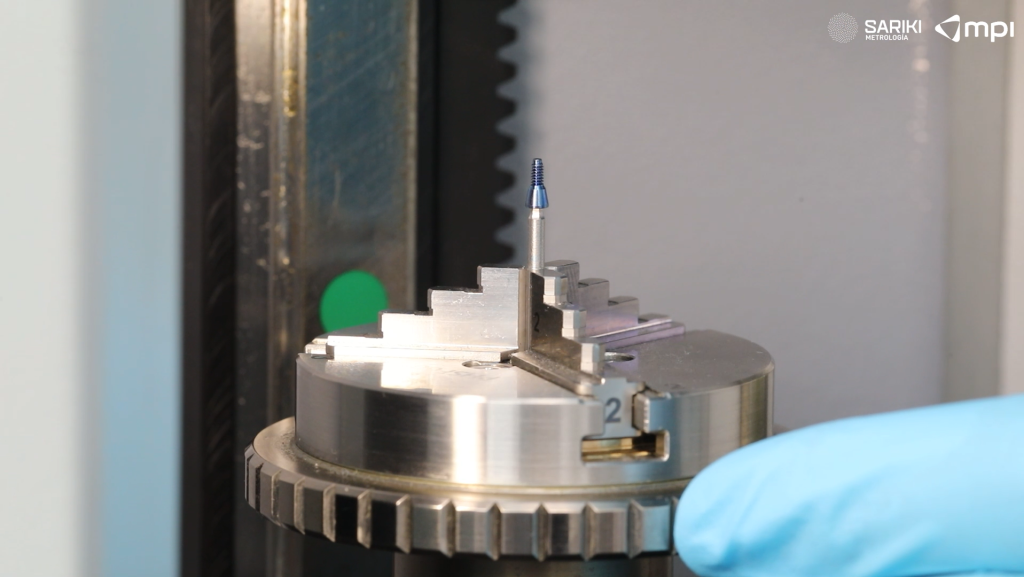

As we wanted to optimize the throughput and the technician’s working times, we decided to develop an optimization in this field together with Sariki. They helped us by proposing to measure our parts with VICIVISION, which is a machine specialized in small parts control.

We have been able to optimize times and improve quality. The fit between implant and connections is essential in the implant sector, as there should be no gaps between surfaces. Thanks to the VICIVISION machine we have been able to achieve this goal.

Surely, VICIVISION is a very complete machine.

It has brought us many benefits, mainly because we placed it in production: operators have direct access to the machine, and they measure the parts every 20 minutes.

Once the machine is programmed, the operator simply places the part and presses the button. Measurement data is saved automatically. With this simple gesture you can identify all the required measures.

In and out of tolerance quotes are color-coded with red and green labels. It is a great time-saver.

Another great advantage is that it is much more reliable than the traditional measurement methods.

The last advantage is that the data saving is automatic in all the measurements, maintaining traceability without losing all these data.