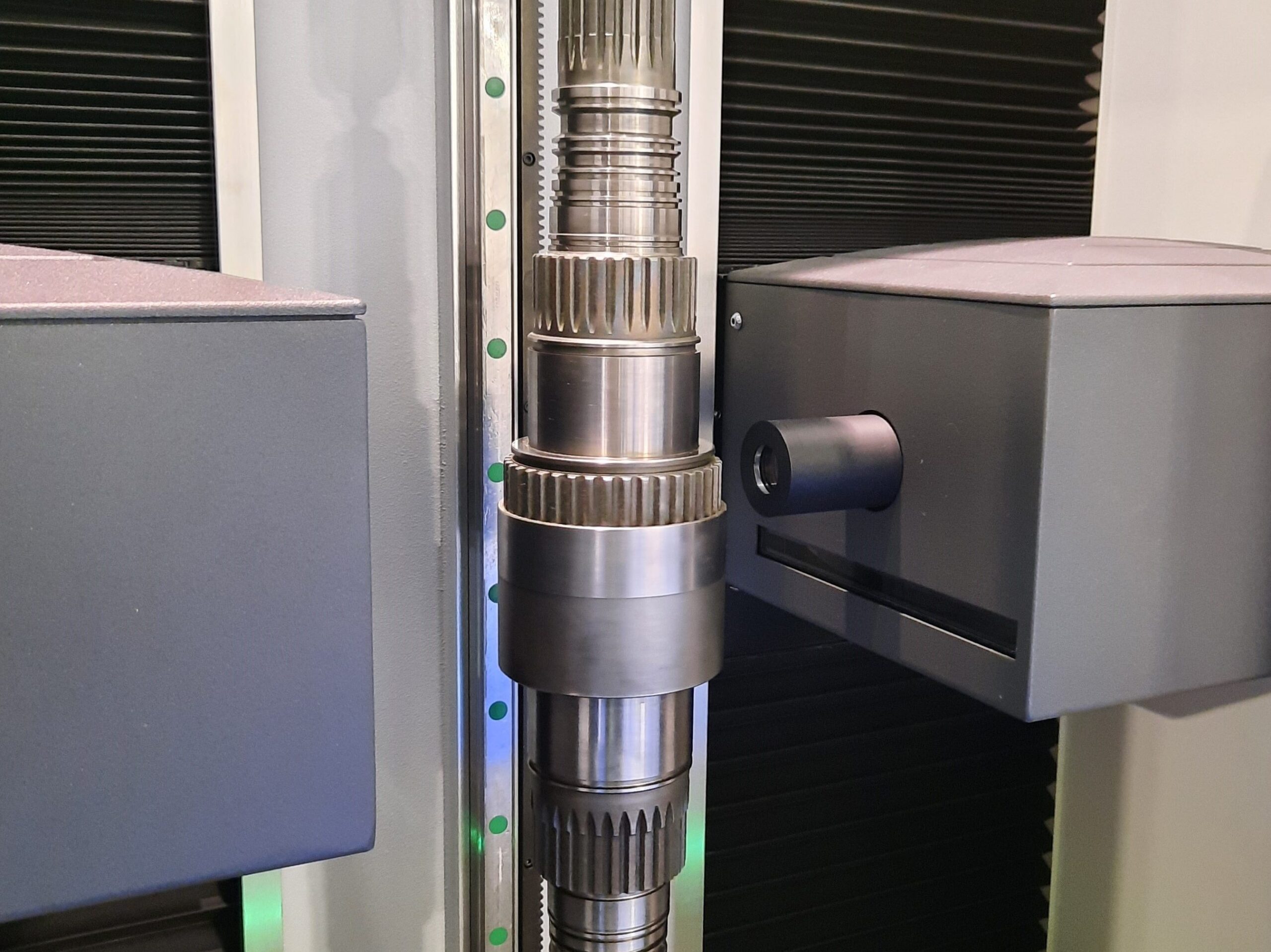

Measure the typical features of splined shafts with a single scan.

VICIVISION presents an innovative solution in metrology to measure splined shafts, combining years of experience in optical measurement with the use of a confocal sensor.

From today, the new VICIVISION measuring instruments can be equipped with a confocal sensor integrated into the machine and capable of covering the entire working range.

Thanks to the patented combination of optical measurement and a non-contact distance sensor, any operator can check splined profiles in a production environment, preserving the typical speed of optical measuring machines and saving up to 95% of time.

In a single measurement cycle, the optical measuring machine provides dimensional measurements and shape errors within seconds and the confocal sensor completes them with additional measurements not detectable via the standard optical system.

The confocal function offers the operator the possibility to measure the typical characteristics of a splined profile:

– Major diameter

– Minor diameter

– Dimension over balls

– Radial runout on pitch diameter

– Coaxiality on pitch diameter.

Download the free flyer and learn how easy it can be to measure splined shafts with the VICIVISION confocal system.