Successful Stories

„Wir haben den After-Sales-Support gefunden, den andere Marken einfach nicht bieten können“ | RIE Srl

Giampaolo di Paoli, Technischer Leiter bei „RIE Srl: „Aus unserer Sicht ist der Messraum der Ort, an dem das Ritual der Perfektion zelebriert wird. Wir haben uns für die M606 Techno entschieden, weil sie genau die richtige Größe für die Art von Teilen hat, die wir bearbeiten. RIE wurde 1980 von zwei Unternehmern und einer„Für Drehteile ist diese Maschine sehr gut“. EZU | VICIVISION

EZU steht für ein zuverlässiges Unternehmen, ein zerspanendes Unternehmen. Wir haben 2016, 100 Millionen Bauteile für die Diesel-Produktion ausgeliefert und wir haben 2017 250 Millionen Bauteile für die Automatikgetriebe ausgeliefert. Daten verlässlich erfassen zu können, dies ist mit dem System von Vicivision einwandfrei gewährleistet. Die Daten, die von der Messmaschine kommen, werden an die Maschine„A must in our industry“: How Ondrives saved hours of time by investing in VICIVISION

VICIVISION UK visited Ondrives, which has origins in the precision gear industry going back more than 80 years. With an outstanding pedigree of knowledge, expertise and experience the company quickly identified VICIVISION UK as the obvious choice for best in class optical measurement machine.

Opting for a model from the flagship TECHNO rang, the M309 ensures reliability in measuring cylindrical parts is second to none, ticking all the boxes for achieving lean manufacturing.

Making immediate inspection and data capture available next to multiple machining centres, to more than one operator, eliminates bottlenecks and leads to a reduction in downtime.

Achieving production confidence through measurement | VICIVISION UK & Technoset

Confidence is a critical and often-cited concept in manufacturing. As businesses strive to prosper in a crowded and highly competitive marketplace, they need certainty that their processes will consistently and efficiently deliver right-first-time parts, so that order books remain full and customers keep coming back. Technoset knows that as well as anyone. For more than 40 years, the Rugby-based company has specialised in creating highly complex, precision machined components on its multi-axis turning and milling centres, using both common and exotic metals. And thanks to VICIVISION UK, they were able to achieve this through high-precision non-contact shaft measurement machines. Offering manufacturers advanced solutions for turned components, with machines that deliver rapid measurement through dual video and light projection technology.

“From a single VICIVISION we can check parts produced on 17 grinding machines”: Bavieri company

For over 50 years, Bavieri Alfeo S.r.l. has specialised in contract machining for grinding, roll forming and lapping.

“I would highly recommend a VICIVISION machine because it saves a lot of time and the machine is accurate.

We use it on all our machines”.

Führend in der Kaltumformung: Defremm investiert weiter in Qualität und entscheidet sich für VICIVISION

Interview mit Mauro Molinari, Werkleiter R&D Manager. “Defremm ist ein Unternehmen aus Lecco, das sich auf die Herstellung von Kleinteilen aus kaltgeformtem Draht spezialisiert hat. In den letzten 10 Jahren hat unser Unternehmen eine umfassende Digitalisierungsüberholung durchlaufen.” Mauro Molinari PLANT DIRECTOR R&D MANAGER “Wir trafen das von der Familie Molinari geführte Unternehmen auf einer derInterview with Sarbo Minuterie Metalliche: “How we increased productivity and drastically reduced inspection time.”

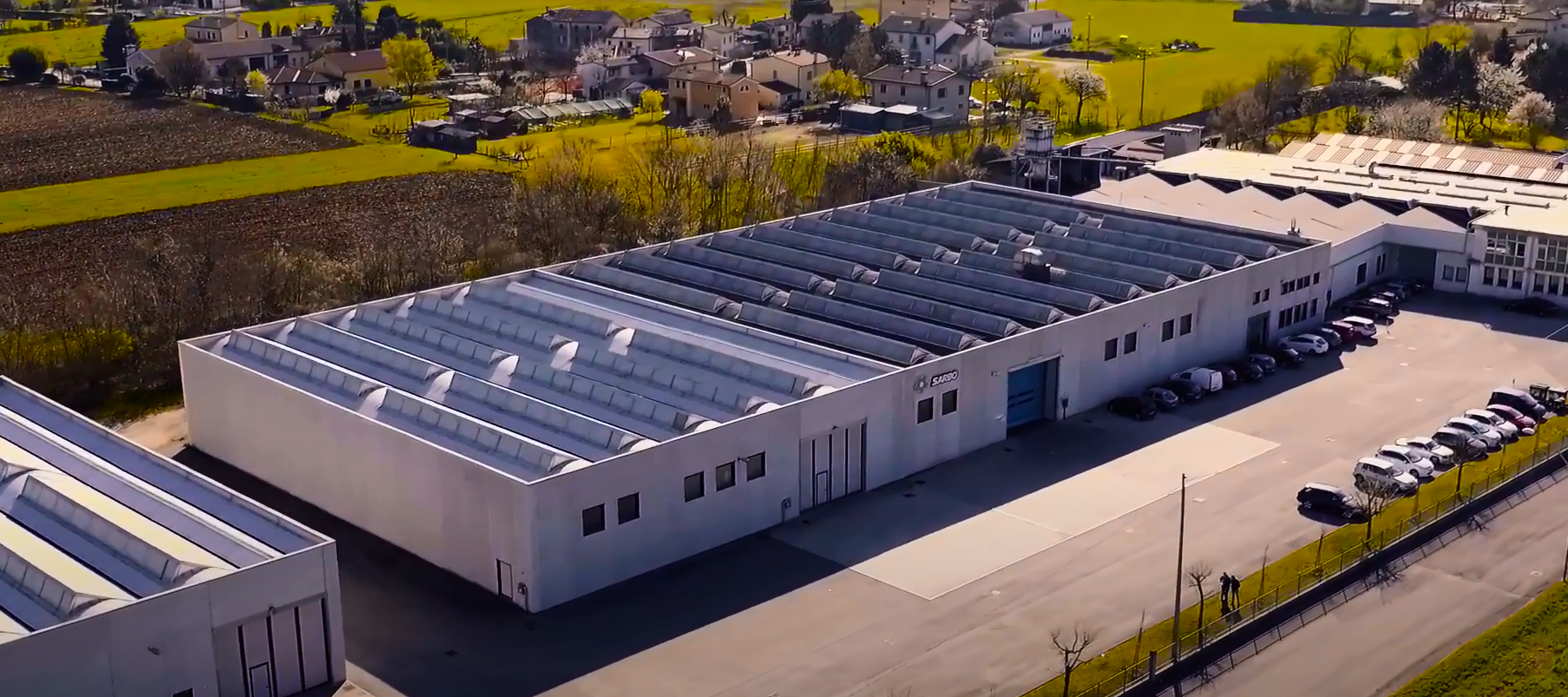

Sarbo S.p.A. is a leading company in the specialized production of bar-turned small metal parts. “From the onset, our staff training is based on a fundamental principle: producing quality.” The company is undergoing a crucial and advantageous period with a generational changeover from partners Luciano Zago and Giuseppe Sartor, to their children, Paolo Zago

Quality control of bar turned parts, Vi-Da

The production of Vi-Da Srl (Darzo, TN) includes all the parts that can be obtained from turning processing: spacers, pins, fittings, pulleys, etc…

Since its establishment in the 1960s, the company decided to focus on the production of special parts characterized by a high level of quality, based on the requests and needs of its clients.

The optical measuring machine VICIVISION MTL is a complete product that is able to execute all the measurements on cylindrical components…

This machine is the ideal instrument for those who, just like Vi-Da, produce special components.

MTL for automated inspection of components: The Vilardell Purtí Group

Vilardell Purtí Group Industrial Division is a worldwide leading company in the manufacture of cutting-off parts and specialized in items of high technical complexity as well as high added value requiring a high level of precision.

The Vilardell Purtí has acquired a VICIVISION machine for production and the automated inspection of components that are manufactured primarily for the automotive sector.

MTL is an optical measuring machine for high-performance revolving parts. In addition to inspection, Vilardell Purtí also uses the VICI system to facilitate parts measurement for production quality verification and adjustment of production machines.