I’m interested in measuring instruments, I wouldn’t say that it’s my calling in life, but I like tinkering around with them, repairing…

My name’s Giordano Cecchini and I’ve been working in Trenton since January 1999.

A company like Trenton, with its good reputation, is a real landmark in this area.

When I started, there were 55 employees, now if you include the personnel in the Fanano plant, there are about 150 of us.

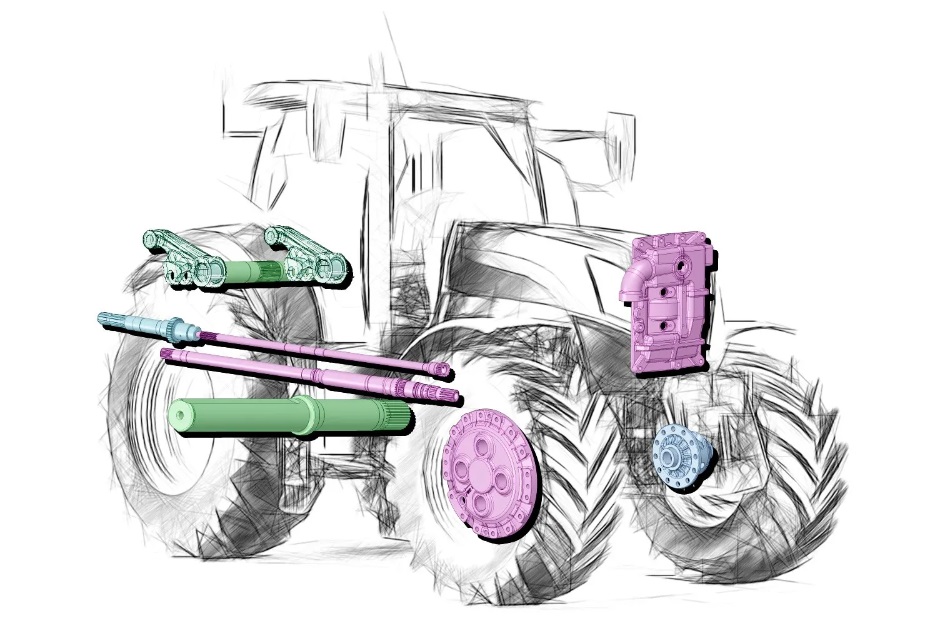

Most of the manufacturing is done in-house, we take care of many different client requests.

Being part of the automotive world is something I’m proud of and a badge of honor for the company.

Working in Trenton gives you a sense of stability and security…

I’m Samuele Fontana, I live here in Frassinoro and I deal mainly with first article inspection both for clients and from suppliers.

Trenton continues to invest in quality and in production to remain a cutting-edge company, capable of manufacturing many parts, from facing & centering to grinding.

We can produce parts up to 1500 mm in length and inspect them on the Vici 2000 mm machine.

One year ago we bought this machine that reaches heights of 2000 mm.

We also have a touchprobe to measure keyway slots and planes.

At the start of production, all the required measurements of the first part are taken.

My name’s Massimo, I’m in charge of quality control. I inspect the first part on the production line to make sure that the measurements are compliant…

The measurements, that range from diameters to distances, radii to angles, are all produced in a single report.

We have a series of grooves here, one, two three, that can be measured in 93,49 seconds with Vici, and that’s really fast. If they’re green that means they’re within tolerance and that’s good. If they’re red, we go to the machine operator and tell them what corrections have to be made.

It’s a really intuitive machine… that’s one of the reasons why I like it.

It makes me laugh when I see my parents using these advanced measuring machines when they find it hard to manage a cell phone. Gen Z is much more tech-native.

A VICIVISION machine is a great return on investment.

The more we use it, the more new programs are uploaded and the more parts we inspect.

It really helps to know we’re starting production off on the right foot, in such a short set up time.

Obviously, having a machine like this means you’re going to be much more accurate than taking measurements manually.

You place the part and while the machine is working, you can do something else.

This machine could be used to carry out inspection on an entire line.

To be competitive in the market in terms of production and quality, we always try to have the best equipment available. Our aim is to be one step ahead and ready to meet all our customers’ needs.