VICIVISION designs and manufactures optical measuring machines

and automation systems.

VICIVISION manufactures non-contact optical machines that measure the external profile of turned and ground parts, which ranges from shafts to micro-mechanical parts used in industries such as dental and watchmaking. VICIVISION measuring systems are distributed worldwide and used directly on the shopfloor. Our machines have been designed to operate effortlessly and efficiently ensuring customers reduce waste while optimizing their investment.

VICIVISION and METRIOS are brands of the Vici & C. S.p.A. group, which has been producing electrical panels and industrial automation systems since 1977. In 2021, Vici & C. recorded a turnover of more than 65 million, with 200 employees, 4 branches, and 40 specialist centers worldwide.

Providing solutions for the industry since 1977

In addition to being a leading international supplier of measuring systems, Vici is an established partner in manufacturing electrical panels, In-Line applications, and industrial automation. It all began in 1977 with the contracted assembly service of circuit boards. Fast forward to 1989 when capabilities expanded to designing and manufacturing automated inspection lines for components in the automotive industry. In 1999, the request for vision systems increased substantially and thus the VICIVISION brand was born.

Our strength comes from an international sales network with a dynamic young team

As the technical and industrial scene rapidly changes, we continue to evolve with it, fueled by the passion of our people. Our company culture fosters the creativity of young people, technical skills, and the latest technological innovations, all within a precise international scope.

« There is no plant, machine, resource or procedure more powerful than the energy that people produce. »

Erick Fantini | Sales Director

Measuring shafts and turned parts

VICIVISION has a worldwide presence in hundreds of turning companies offering a wide range of solutions for measuring shafts and turned parts. All our measuring systems are designed to operate on the shopfloor.

Our optical measuring machines increase the productivity of turning centers by incorporating metrology into production through a simple and quick process. Parts produced from each batch are measured on the shop floor which can significantly decrease the production set up time and in process checks.

VICIVISION is designed to perform next to a CNC machine saving hours in inspection time and reducing downtime caused by tool wear. This also keeps production in constant tolerance, using the data acquired by the Vici for tool offset compensation.

Today’s market demands certified quality products, pushing manufacturers to be more mindful of new requests and increasing investments in inspection equipment.

Production capacity depends on many different factors often influenced by the setup and downtime of the machines. Producing quality products at the right price is the primary focus for companies in maintaining their competitive advantage.

VICIVISION was designed to accommodate this need by inspecting parts with a simple and efficient tool, making our product a worthwhile investment.

Electrical panels

We have always been one step ahead in the supply of electrical panels and In-Line applications. An ordinary service, but with extraordinary efficiency from design to production.

In-Line control

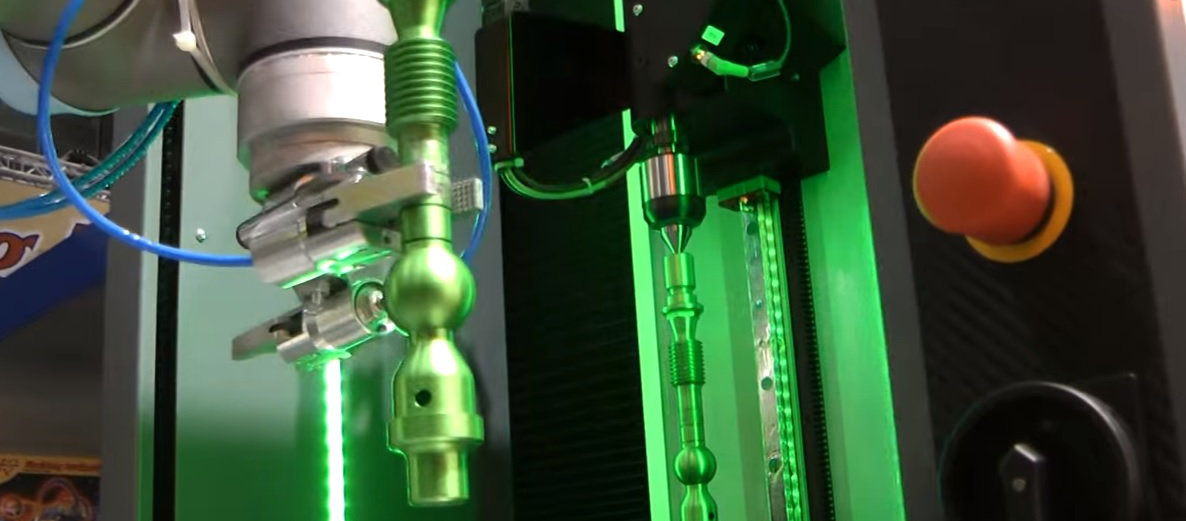

Our custom machine department designs and installs robotic cells and vision systems for 100% inspection in production. These In-Line Metrology solutions ensure accuracy and measurement repeatability in a short machine cycle.

![VICIvision-[Converted]](https://www.vicivision.com/wp-content/uploads/2014/11/VICIvision-Converted-300x66.jpg)